28 Aug Is It Time For A Control Retrofit for Your Machine?

A control retrofit on a CNC machine consists of an upgrade to the entire control system of the machine. How do you know if this is the right solution for your equipment and your business needs? In this article we will discuss that in depth, along with other options for your aging equipment.

Depending on the age of your equipment, you may be at risk for significant downtime even if your machine seems to be running flawlessly. How can this be? In many cases, older control systems have obsolete parts, meaning that once a failure occurs, you may be in trouble when it comes to finding replacement parts. Machine control systems are designed to work as a unit; when a part fails on a system, you typically cannot use a similar part from a different manufacturer, or in many cases, you cannot use newer generation parts from the same manufacturer due to compatibility issues.

Where does this leave you as a machine owner? It is wise to research and und

erstand the exact situation you may be in. Do you have a control system on your equipment made by a company that no longer produces machine controls? Is your system obsolete, and are parts virtually impossible to source when a failure occurs? How big of an impact will you face if your control system encounters problems, and you are down for an extended period, scouring the web for used parts? These answers will vary based on your individual business.

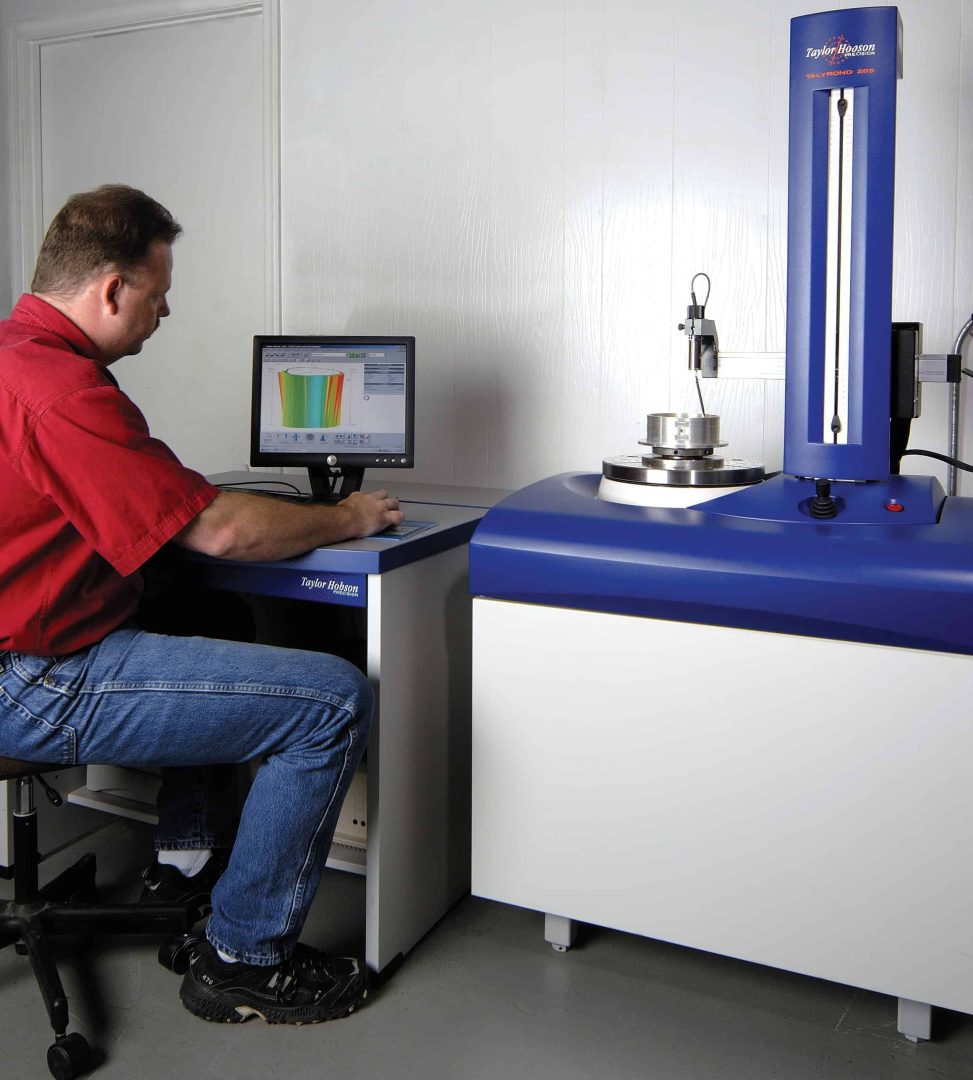

Another aspect to consider is your equipment’s performance. In some instances, you may have an older machine with controls still supported by a major manufacturer. While this is great news, you should still evaluate that machine’s performance and speed. Is the shop across town taking potential work from you because they have a speed advantage from new equipment? Today’s control systems can process and run much quicker and efficiently, with cutting functions and cycles that many older controls simply couldn’t handle. Modern controls are also “smarter,” capable of monitoring information like pressures, temperatures, battery life, tool life, torques, etc. helping to keep downtime at bay, and they can be customized to your specific needs.

Perhaps you need more speed from your equipment but don’t want to invest in a new machine? Reach out to a controls retrofit company like Schmiede Corporation. Typically, we can retrofit your machine with new controls and a full warranty for a fraction of the price of a new machine, giving you a competitive advantage of new controls without the overhead costs.

What does this process look like? One advantage to working with Schmiede is project customization. We offer full machine rebuilds, way grinding, hand scraping, custom painting, electrical retrofitting, and much more. Can’t afford to pull your machine out of service? We have a state-of-the-art machine shop that in many instances can support your machining needs during a retrofit and rebuild, further reducing impact on your business.

Still not sure if your machine is a good candidate for a control retrofit? Interested in adding Motion Controls to a manual machine but don’t need a full CNC system? Give Schmiede a call and talk with one of our experts today.